Metal

When we study the elements, it is important to know which elements are metals and which ones are not. If you are trying to learn to distinguish between metals and non-metals, a list and their uses is a good way to break them down and help memorize the difference between the two. The good news is that most elements are metals. A useful way to approach the study of elements is to distinguish whether they are metal or non-metal. Metals share some common properties. So, knowing what are those properties is a good way to begin our study.

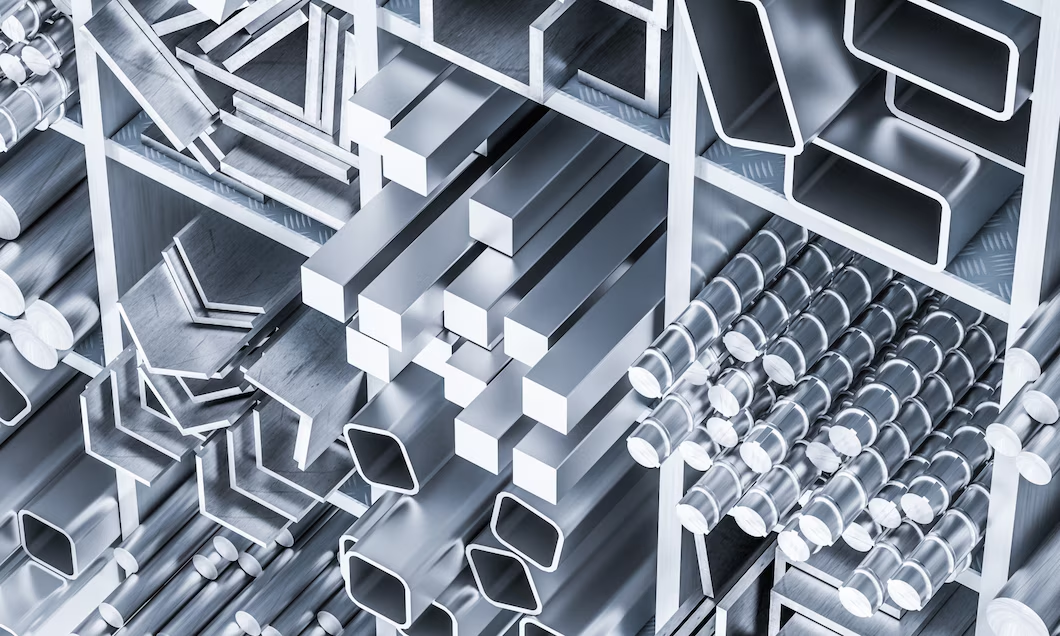

Most metals have a solid state when they are at room temperature. Another way to recognize a metal is that they tend to be shiny. Metals also tend to be a good conductor of heat and electricity. But have low ionization energies and low electronegativities. Another important property that many metal elements share is that they are malleable. This means that metals are relatively easy to be broken up into sheets. Also, most metals can be made into wire. This is what we know as being ductile. With the exception of potassium, lithium, and sodium, most metals have a high density. One of the common and, perhaps, most noticeable properties that most metal elements share is that they corrode when exposed to seawater or air. Finally, most metal elements lose electrons during reactions.

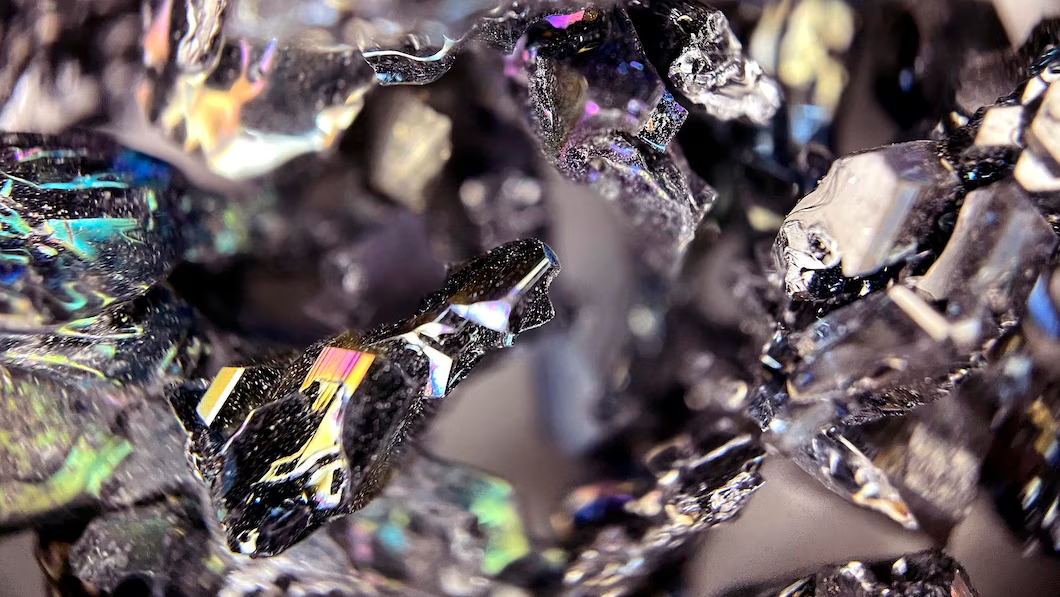

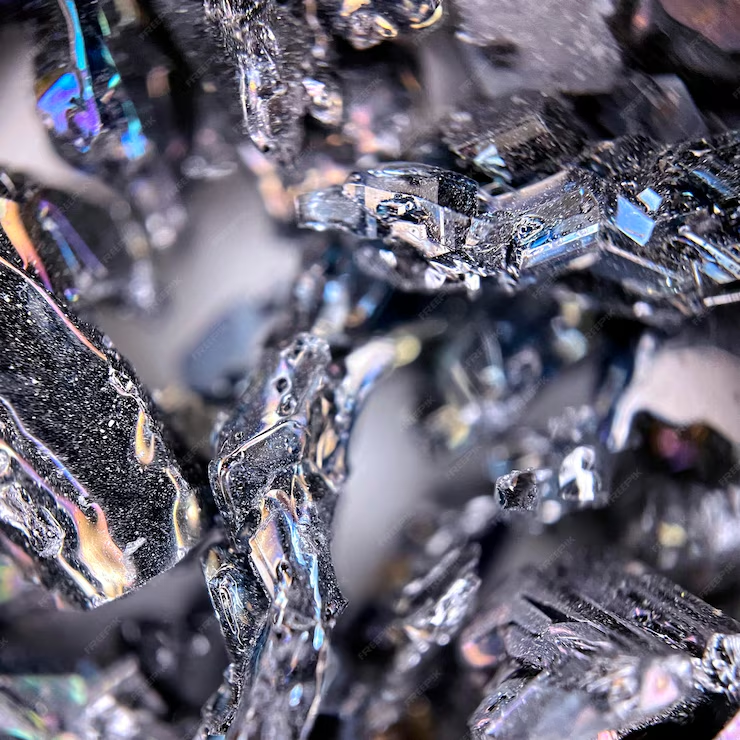

Iridium

Iridium was discovered and named by a British scientist, Smithson Tennant. About 1800 he began an extended association with W. H. Wollaston in London for the purpose of improving the technology of the fabrication of platinum. This metal had for some time been known to dissolve almost completely in aqua regia, but a small black residue always remained and was for a time thought to be graphite. In the summer of 1803 Tennant began a study of this material which ultimately resulted in the identification of both osmium and iridium Almost simultaneously in France, L. N. Vauquelin and A. F. de Fourcroy, in Paris were working on the black residue left after three successive extractions of native platinum with aqua regia and proposed the existence of a new element. These observations were complemented by H.V. Collet-Descotiles. There can be no question that Tennant’s work owed much to the French research but he displayed greater insight than the latter. Iridium is a precious metal. It’s the densest element known and has the highest corrosion resistance. Its mechanical is notable such as its elasticity (the second, after osmium). Iridium is hard, fragile and can be easily worked between 1200 oC and 1500 oC.

Taitanium

Titanium is a chemical element; it has symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resistant to corrosion in sea water, aqua regia, and chlorine.

Titanium was discovered in Cornwall, Great Britain, by William Gregor in 1791 and was named by Martin Heinrich Klaproth after the Titans of Greek mythology. The element occurs within a number of minerals, principally rutile and ilmenite, which are widely distributed in the Earth’s crust and lithosphere; it is found in almost all living things, as well as bodies of water, rocks, and soils. The metal is extracted from its principal mineral ores by the Kroll and Hunter processes. The most common compound, titanium dioxide, is a popular photocatalyst and is used in the manufacture of white pigments. Other compounds include titanium tetrachloride (TiCl4), a component of smoke screens and catalysts; and titanium trichloride (TiCl3), which is used as a catalyst in the production of polypropylene.

Titanium can be alloyed with iron, aluminium, vanadium, and molybdenum, among other elements, to produce strong, lightweight alloys for aerospace (jet engines, missiles, and spacecraft), military, industrial processes (chemicals and petrochemicals, desalination plants, pulp, and paper), automotive, agriculture (farming), medical prostheses, orthopedic implants, dental and endodontic instruments and files, dental implants, sporting goods, jewelry, mobile phones, and other applications.

The two most useful properties of the metal are corrosion resistance and strength-to-density ratio, the highest of any metallic element. In its unalloyed condition, titanium is as strong as some steels, but less dense. There are two allotropic forms and five naturally occurring isotopes of this element, 46Ti through 50Ti, with 48Ti being the most abundant (73.8%).

Zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. Zinc is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic table. In some respects, zinc is chemically similar to magnesium: both elements exhibit only one normal oxidation state (+2), and the Zn2+ and Mg2+ ions are of similar size. Zinc is the 24th most abundant element in Earth’s crust and has five stable isotopes. The most common zinc ore is sphalerite (zinc blende), a zinc sulfide mineral. The largest workable lodes are in Australia, Asia, and the United States. Zinc is refined by froth flotation of the ore, roasting, and final extraction using electricity (electrowinning).

Zinc is an essential trace element for humans, animals, plants and for microorganisms and is necessary for prenatal and postnatal development. It is the second most abundant trace metal in humans after iron and it is the only metal which appears in all enzyme classes. Zinc is also an essential nutrient element for coral growth as it is an important cofactor for many enzymes.

Zinc deficiency affects about two billion people in the developing world and is associated with many diseases. In children, deficiency causes growth retardation, delayed sexual maturation, infection susceptibility, and diarrhea. Enzymes with a zinc atom in the reactive center are widespread in biochemistry, such as alcohol dehydrogenase in humans. Consumption of excess zinc may cause ataxia, lethargy, and copper deficiency. In marine biomes, notably within polar regions, a deficit of zinc can compromise the vitality of primary algal communities, potentially destabilizing the intricate marine trophic structures and consequently impacting biodiversity.

Brass, an alloy of copper and zinc in various proportions, was used as early as the third millennium BC in the Aegean area and the region which currently includes Iraq, the United Arab Emirates, Kalmykia, Turkmenistan and Georgia. In the second millennium BC it was used in the regions currently including West India, Uzbekistan, Iran, Syria, Iraq, and Israel.Zinc metal was not produced on a large scale until the 12th century in India, though it was known to the ancient Romans and Greeks. The mines of Rajasthan have given definite evidence of zinc production going back to the 6th century BC. To date, the oldest evidence of pure zinc comes from Zawar, in Rajasthan, as early as the 9th century AD when a distillation process was employed to make pure zinc. Alchemists burned zinc in air to form what they called “philosopher’s wool” or “white snow”.

The element was probably named by the alchemist Paracelsus after the German word Zinke (prong, tooth). German chemist Andreas Sigismund Marggraf is credited with discovering pure metallic zinc in 1746. Work by Luigi Galvani and Alessandro Volta uncovered the electrochemical properties of zinc by 1800. Corrosion-resistant zinc plating of iron (hot-dip galvanizing) is the major application for zinc. Other applications are in electrical batteries, small non-structural castings, and alloys such as brass. A variety of zinc compounds are commonly used, such as zinc carbonate and zinc gluconate (as dietary supplements), zinc chloride (in deodorants), zinc pyrithione (anti-dandruff shampoos), zinc sulfide (in luminescent paints), and dimethylzinc or diethylzinc in the organic laboratory.

Brushed Metal

Brushed metal is metal that has been abraded (“brushed”), usually with a fine grit sandpaper. The brushing gives the metal a distinctive look, as it retains some but not all of its metallic lustre and is given a pattern of very fine lines. It can be compared to metal with several small scratches all running in the same direction. Commonly used metal for brushing include stainless steel and nickel.